Disclaimer: The views and opinions expressed in this article posted on this website are those of the author and do not necessarily reflect the official position of the persons, parties, and institutions mentioned.

Before everything else, I would like to express my gratitude to all the organizers, sponsors, participants, and fellow judges for making this virtual event a successful one. A special thank you to the organizers for entrusting me with the duty to serve as a judge for the homebrew category. Congratulations to all the winners and participants. Brewing to beat a deadline and sticking your neck out there is not an easy task. I look forward to meeting and talking about beer with the participants from the homebrew category. The list of winners can be found at the end of this article.

THE COMPETITION

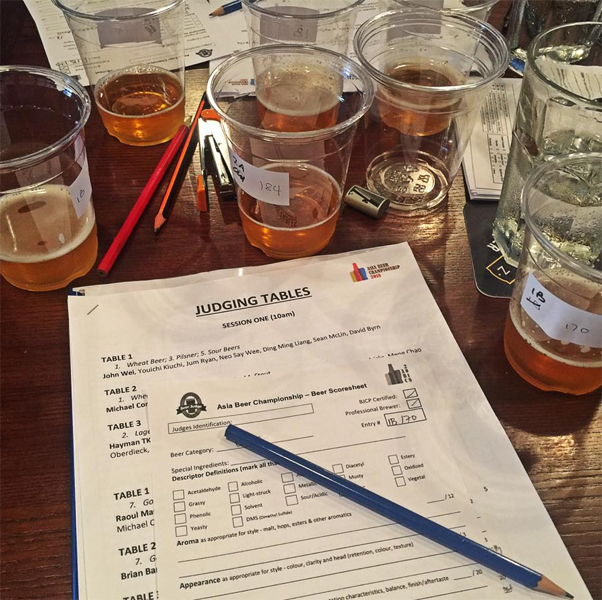

After delays due to national quarantine restrictions, the First Craft Beer Association of the Philippines (CBAP) Beer Competition was finally concluded last 10 April 2021. The competition featured two categories, homebrew (20 entries) and commercial (18 entries), with three judges assigned randomly to each. Judges evaluated the beers blind using the beer score sheet of the Beer Judge Certification Program (BJCP). Further, the registration fee was inclusive of free supplies from the sponsors, which included five kilograms of base malts, 100 grams of Talus hops, and three 11 gram-packs of brewing yeast for each participant.

The 2015 BJCP Beer Style Guidelines for American IPA (21A) was the benchmark for the competition and was announced ahead of the judging proper. A BJCP Certified Beer Judge was tapped as a consultant for the competition who briefed the judges on the best practices. For more information about the event, you may get in touch with the CBAP.

LESSONS LEARNED AS A BEER JUDGE

While writing beer reviews is a hobby of mine, I never really had the chance to judge beers in a competitive context. To be a Certified Beer Judge and to serve in various competitions around the world are two of my current goals. To achieve these ambitions, I know that I must maximize every opportunity presented, such as this competition, to learn as much as I can.

Below are five key lessons learned from my first experience in competitive beer judging:

1. BE OBJECTIVE; USE WORDS THE BREWERS CAN RELATE TO.

Brewing competitions are for the brewers; therefore, judges ought to provide constructive and objective feedback on the beers submitted. Since people have different palates, sensitivities, and vocabularies, I learned that a more appropriate way to describe beer characteristics like aroma and flavor is by using a standardized set of descriptors coupled with quantifiers (e.g., low, medium, high).

For instance, one of my favorite descriptors is “charred fruit skin.” This is something my friends (who are also coffee enthusiasts and roasters) and I use often to describe that distinct burnt, ashy, or “carbony” character we associate with grilled fruits like tomato or apple. It is very descriptive– yes– but from a brewer’s perspective, it may not be relatable. Brewers do not have the time to flare up a grill just to figure out what I wanted to describe. In hindsight, better words would have been “burnt” or “charred,” as these could be easily looked up in the style guidelines or other technical references.

“This beer smells like my grandmother’s attic when I was 12 years old.” “Musty” is a better and more concise word. “Musty” aromas and flavors, which are also described as being earthy, moldy, or like damp cellars, old books, or decomposing wood by the BJCP, are undesirable characteristics that may suggest oxidation among others. Unless you organize a field trip with the brewers to your grandmother’s attic, then it is probably best to just use “musty” or the related adjectives mentioned.

As aids, aroma and flavor wheels can be used. The ones we use frequently are Randy Moshers’ Aroma Spiral, Malt Flavor Wheel, and the Hop Spider Chart. For off-flavors, the Beer Faults list by the BJCP can be referred to.

2. A “DELICIOUS” BEER WOULD MOST LIKELY SCORE LOW IF ENTERED IN THE WRONG CATEGORY.

For example, if you have an “IPA” that was fermented using a very expressive Belgian yeast strain and showcased a complex Belgian Tripel-like aroma profile of spices, fruity esters, and clove-like phenols, chances are, your beer would score low if entered into the American IPA (21A) category, even if it is “technically flawless” and “delicious.” Holding all else equal, your entry would probably fare better as a Specialty IPA: Belgian IPA (21B).

When in doubt, you can always consult with a Certified Beer Judge or a seasoned brewer. You can also look up past winners in international brewing competitions such as the Great American Beer Festival as well as the Asia Beer Championship, and even buy the winning beers if these still available. Otherwise, you can have trusted friends evaluate your beer and compare it with reviews online. My favorite ones are the Judges’ Reviews on The Beer Connoisseur written by Certified Beer Judges, with some even holding Grand Master ranks.

3. THE WHOLE IS GREATER THAN THE SUM OF ITS PARTS.

In my opinion, evaluating beer is still a form of art with its subjectivity arising mainly from the unique palates and sensitivities of people. No two snowflakes are alike; the same can be said for beer judges. I think this is one of the reasons why international competitions such as the GABF select judges from a list of internationally recognized brewers, sensory experts, suppliers, writers, and consultants. These individuals are chosen based on formal sensory training; experience in evaluating beers on flavor panels and/or at competitions; judging demeanor; knowledge of beer styles and brewing process; as well as industry and peer recognition. Rookie judges also compose roughly 10 percent of the GABF panel to keep it fresh with new ideas and palates. These rookies should be able to communicate in fluent written and verbal English, have formal sensory training, and must be regulars in flavor panels or competitions.

Judges are limited by their sensitivities. In a panel, you may have someone who is very sensitive to diacetyl (buttery, butterscotch, and movie popcorn) but could not detect acetaldehyde (fresh cut green apples, grass, green leaves, and latex paint). The others who are very sensitive to acetaldehyde, for example, could compensate for the first one mentioned. In a perfect world, these differences would be “smoothened out” the more qualified judges are present, keeping other things constant.

Before judging, we were able to talk to each other about our respective strengths and weaknesses regarding these off-notes. So far, I am sensitive to astringency, mustiness (stale, moldy, and cellar-like), oxidation (stale, papery, and cardboard), phenolic (clove, pepper, vanilla, etc.), and yeastiness (bready, sulfur-like). However, I still need further sensory training to really master the other common off-notes such as acetaldehyde and maybe dimethyl sulfide (DMS) (sweet, cooked, or canned corn-like aroma and flavor at low levels).

After the initial scoring, judges calibrate and deliberate their respective scores. These are very important processes in determining the winners from each category. The best practice is to have a variance ceiling of seven points from the consensus for scoring accuracy for each exam beer. For judges in the American IPA (21A) category, for instance, this is when you would justify why Beer A, an entry with an intense citrus American hop aroma (style-appropriate) but has a low solvent-like flavor (inappropriate), should be ranked higher than Beer B, an entry plagued with inappropriate characteristics such as a prominent musty aroma and a moderate paper-like flavor.

4. TROUBLESHOOTING IS NOT BLACK AND WHITE.

As a reviewer and not a brewer, I am limited by my lack of brewing experience and can only provide feedback based on my sensory notes. These will be consumer-oriented comments with regard to the overall impression or presentation such as “Tone down the bready character,” “Use more citrus-forward hops,” or generic troubleshooting tips like “Check for infection,” lifted from the BJCP Beer Faults list, which is a summarized version of the section from the study guide.

Fortunately, I was teamed up with Jaime Fanlo, Head Brewer of Pedro Brewcrafters. During our deliberation, we discussed the off-flavors we noted and their potential causes. The brewing process is complex, and troubleshooting is apparently much more complicated than “Do this,” or “Do that.” Identifying the root causes of these flaws, likewise, becomes a Herculean feat since we cannot simply speculate or make rash assumptions about how the brewer made his/her beer. In fact, our technical feedback was based solely on the guidelines and the fermented liquid in our glasses.

Often, off-notes or flaws are not contributed by a single, easy to predict source. They can arise from a myriad of possible factors, conditions, or inputs during the brewing process. Identifying these issues can be very challenging for a brewer. The quality of the beer can also be affected by other factors beyond the brewer’s control, such as handling and proper storage by the end consumer. Some of the issues may even only surface a few weeks or months down the road. For example, in late 2020, the brewing behemoth Guinness had to recall alcohol-free beers two weeks after these were released as a “precautionary” measure due to “microbiological contamination.” In 2017, Sierra Nevada, the third-largest craft brewery in the United States at that time, recalled eight beer products due to bottle flaws that could cause glass-related injuries. I guess product recall provisions exist for a reason.

These realizations were reinforced by insights from previous discussions with Raoul Masangcay, Certified Beer Judge and Head Brewer of Elias Wicked Ales & Spirits. He mentioned that when scaling up a brewery, the problems you will encounter also scale up not just in a linear fashion but exponentially. For Raoul, constructive feedback from judges, especially in sanctioned competitions, has helped him see through the haze in addressing the flaws of his beers and brewing methods. Consequently, armed with his brewing experience and knowledge from his rigorous training as a Certified Beer Judge, he has been able to provide sound technical advice on beers.

All in all, it seems I have gained a deeper appreciation of the intricacies of the brewing process by seeing things from a brewer’s perspective. Maybe it is time for me to take brewing classes or visit friends during their brew days so I can immerse myself fully in the practical and much more daunting side of the craft.

5. A PROBLEMATIC BEER MAY STILL BE BETTER THAN NO BEER.

There are a lot of valid reasons why a brewer could not participate in a competition, but a participant that had entered a beer and received a “Problematic” score or rating should not be discouraged. At the end of the day, that person leaves the competition with technical feedback about his/her brew and gets to improve on it. Hopefully, these would translate to higher scores and even a fighting chance to bring home the bacon in the next competitions.

Feel free to get in touch with the competition winners through their Instagram accounts:

Homebrew Category:

Gold: Gib Osbert Ang (GaVoBrews)

Silver: Gresham Deolal (Greshbrew Homebrew)

Bronze: Irwin Carlo Go (Beerwin Artisanal Brewery)

Commercial Category:

Gold: James Mitchell (Mitchell’s Backyard Brewery)

Silver: Enrico De Jesus (Madbul Cerveza Artesana)

Bronze: John Jason Silamor (3006 Craft Brewery)